Cardboard Boxes and Packaging for Lithium Batteries: Safe and Sustainable Solutions with RhinoPack

- Tim Turner

- Feb 26, 2025

- 4 min read

Updated: Jan 27

Cardboard boxes and packaging for lithium batteries are essential for safely transporting and storing these powerful yet sensitive energy sources.

With global lithium battery shipments exceeding 2 billion units in 2023, the demand for reliable lithium battery packaging has never been higher.

Whether you’re shipping small cells or industrial-grade packs, cardboard-based battery packaging solutions offer a perfect blend of strength, compliance, and sustainability.

In this guide, we’ll dive into how RhinoPack’s cardboard sheets, crates, corners, and pallets create top-tier packaging materials for lithium batteries, ensuring your products stay secure and eco-friendly.

Why Choose RhinoPack Cardboard for Lithium Battery Packaging?

Cardboard boxes and packaging for lithium batteries stand out as a practical, safe, and green option for businesses.

Lithium batteries require careful handling due to their potential for overheating or short-circuiting—over 200 incidents were reported in air transport between 2010 and 2020, according to the FAA https://www.faa.gov/hazmat/resources/lithium_batteries

Cardboard’s versatility makes it ideal for lithium battery shipping solutions, offering durability without the environmental drawbacks of less sustainable materials.

Key Advantages of Cardboard Battery Packaging Solutions

Cardboard shines in lithium battery packaging systems for several reasons:

Lightweight Strength: Provides robust protection without adding unnecessary weight.

Eco-Friendly: Recyclable and biodegradable, aligning with green practices.

Custom Fit: Easily tailored to battery sizes, as seen with RhinoPack’s offerings at https://www.rhinopack.co.uk/bespoke-boxes-custom-box-design

Using cardboard sheets, crates, and corners ensures your lithium battery shipping solutions meet both safety and sustainability goals.

RhinoPack’s Cardboard Solutions for Lithium Battery Packaging

We craft these solutions with precision, offering unmatched durability and flexibility to protect your lithium batteries, no matter the application.

Plus, we can tailor every piece to any size, any colour, and any shape, ensuring a perfect fit for everything from tiny button cells to massive industrial packs. Whether you need a unique design to match your brand or a specific configuration for safe shipping, RhinoPack delivers bespoke battery packaging solutions that stand out.

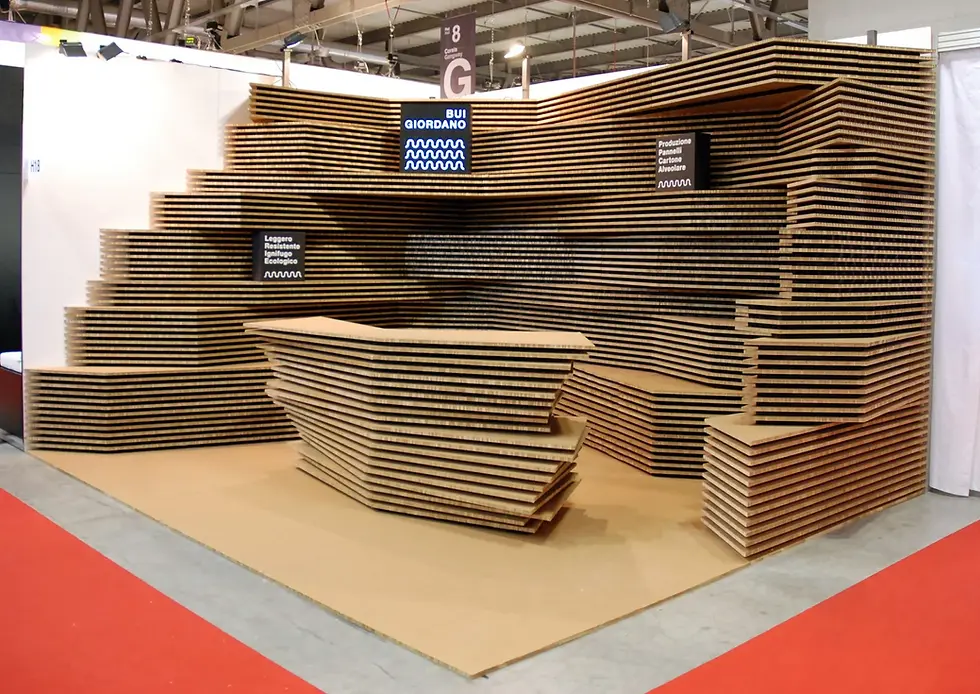

Strong Cardboard Sheets: Perfect for layering or wrapping batteries, these sheets offer impact resistance and flexibility https://www.rhinopack.co.uk/honeycomb-cardboard-sheets

Honeycomb Cardboard Pallets: Lightweight yet sturdy, these pallets support stacked battery loads securely https://www.rhinopack.co.uk/honeycomb-cardboard-pallet-manufacturer

Cardboard Edge Protectors: Reinforce packaging to prevent crushing during transit https://www.rhinopack.co.uk/strong-cardboard-edge-protectors

RhinoCrate Alternatives: A sustainable substitute for wooden crates, ideal for heavy-duty lithium battery containment systems https://www.rhinopack.co.uk/post/rhinocrate-the-wooden-shipping-crate-alternative

These solutions steer clear of static risks tied to less suitable materials, prioritizing safety for lithium battery packaging.

Eco-Friendly Lithium Battery Shipping Solutions

Sustainability is critical.

The EPA reports an 88.8% cardboard recycling rate in 2020 https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/paper-and-paperboard-material-specific-data

RhinoPack’s cardboard boxes and packaging for lithium batteries reduce waste while meeting rigorous safety standards.

For more on sustainable alternatives to traditional packaging like bubble wrap or plastic, check out our blog at https://www.rhinopack.co.uk/post/eco-friendly-alternatives-to-bubble-wrap-protecting-products-and-the-planet

Meeting Lithium Battery Packaging Regulations with Cardboard

Compliance is non-negotiable for lithium battery shipping solutions.

The UN38.3 standard mandates packaging that withstands drops, vibrations, and temperature changes https://unece.org/fileadmin/DAM/trans/danger/publi/unrec/Rev19/English/UN38.3.pdf

Additionally, regulations like UN3480, which specifically address loose lithium-ion batteries, require robust packaging to prevent short circuits and damage during transport https://www.gwp.co.uk/guides/un3480-regulations

RhinoPack’s cardboard crates and sheets are designed to pass these tests, ensuring your battery packaging solutions meet global requirements.

Tailoring Cardboard for Lithium Battery Containment Systems

Different batteries need different approaches.

Small cells benefit from layered cardboard sheets https://www.rhinopack.co.uk/honeycomb-cardboard-sheets while larger packs thrive in RhinoCrates or on honeycomb pallets https://www.rhinopack.co.uk/honeycomb-cardboard-pallet-manufacturer

Edge protectors add stability for stacked shipments, ensuring comprehensive lithium battery packaging. For tips on protecting fragile items during shipping, see our guide at https://www.rhinopack.co.uk/post/safely-shipping-fragile-products-overseas-the-ultimate-guide.

Optimizing Your Cardboard Packaging Process for Lithium Batteries

Efficiency in cardboard boxes and packaging for lithium batteries saves time and resources. Here’s how to streamline:

Assess Battery Needs: Match sheets or crates to battery dimensions and weight.

Reinforce with Corners: Use edge protectors for added durability https://www.rhinopack.co.uk/strong-cardboard-edge-protectors

Leverage Pallets: Stack efficiently with honeycomb pallets https://www.rhinopack.co.uk/honeycomb-cardboard-pallet-manufacturer

Bulk Up: Order in bulk to cut costs https://www.rhinopack.co.uk/post/cost-savings-from-bulk-orders-of-cardboard-boxes

Cost-Effective Battery Packaging Solutions

A 2022 NREL study showed optimized packaging reduced shipping damages by 30% https://www.nrel.gov/docs/fy22osti/81645.pdf

RhinoPack’s durable cardboard sheets and crates minimize returns, making your lithium battery shipping solutions both affordable and reliable.

For more on protecting shipments, read our blog at https://www.rhinopack.co.uk/post/how-to-protect-parcels-from-courier-damage-in-the-uk

FAQs About Cardboard Boxes and Packaging for Lithium Batteries

Q: How do cardboard boxes ensure lithium battery safety?

Cardboard sheets and crates provide cushioning and static resistance, meeting standards like UN38.3

Q: Are RhinoPack’s pallets suitable for heavy batteries?

Yes, our honeycomb cardboard pallets handle significant loads securely https://www.rhinopack.co.uk/honeycomb-cardboard-pallet-manufacturer

Q: What regulations apply to lithium battery packaging?

UN38.3 and IATA rules govern lithium battery containment systems—RhinoPack’s solutions comply fully.

Q: Why avoid plastic in battery packaging?

Plastic can generate static and isn’t as eco-friendly as cardboard. Discover better alternatives in our blog at https://www.rhinopack.co.uk/post/eco-friendly-alternatives-to-bubble-wrap-protecting-products-and-the-planet

Conclusion

Cardboard boxes and packaging for lithium batteries deliver unmatched safety, sustainability, and efficiency. RhinoPack’s sheets, crates, corners, and pallets create tailored lithium battery packaging that protects your products and the planet. Ready to enhance your battery packaging solutions?

Contact RhinoPack today for custom cardboard options that power your success.

Looking for the best packaging protection?

Contact us today to discuss your specific requirements and get a quote!

If you have any other questions, you may find the answers here - https://www.rhinopack.co.uk/faq

Come join us - https://www.facebook.com/RhinoPack.co.uk

Or find us here - https://maps.app.goo.gl/f9Jhd1PWL9ho7MkVA